More and more often new cars seem to be featured with electronic defects. It also appears from research by JD Power. Especially fully electric models and plug-in hybrids often leave their drivers. Autoweek found out where that trend comes from and how manufacturers solve the defects.

What is not on it cannot go wrong and with that old folk wisdom in mind it is quite logical that malfunctions of new cars are increasingly due to failing electronics. Figures from the American research agency JD Power underline that. A salient detail is that the number of problems with a hundred cars, called JD Power PP100 in the statistics, at Doorsnamergensen 181 is (figures for 2024, American market), but is no less than 230 among the premium brands. That depends on the more complicated on -board systems and the resulting dependence on connectivity, the researchers explain these unrest -bearing numbers.

Electric cars less maintenance and fault sensitive? The opposite appears to be the case!

JD Powers further lies the often heard statement that electric cars need less maintenance and are less sensitive to interference than models with a combustion engine, because they contain fewer parts and components. The opposite appears to be the case. According to JD Powers Automotive CEO Frank Hanley, drivers of fully electric cars and plug-in hybrids report on average three times as often in the workplace with malfunctions than motorists who control a vehicle with conventional drive.

Nevertheless, the biggest problem roots that you also encounter in modern fuel cars are: false or incomprehensible warning signals of the ADAS, malfunctions in the connection with the smartphone and the new operation of road -cutting physical buttons and levers. In the latter area, especially Tesla gets a lot of JD Power Falie.

Time pressure cause errors

Admittedly, JD Power limits his research area to the United States, but also on our side of the Atlantic Ocean we cannot ignore this phenomenon, according to a number of cases that occurred in recent years. You can really wonder how it is possible that car manufacturers, where hundreds of highly educated engineers work out of the seam on things that are subsequently tested in detail in the most extreme circumstances, so often fall stitches.

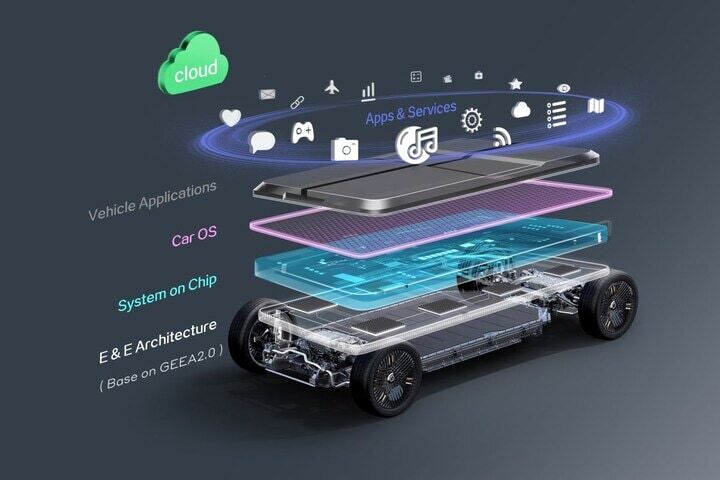

It is often time pressure that causes construction errors. That is the case: the development of cars has gained momentum in recent years. That is largely in the rise of the various forms of electrification, but the range of ADAS on board also increases enormously. Moreover, cars are increasingly being connected and we expect (and get) more and more luxury on board.

Newcomers weigh pressure

All in all, you can safely conclude that considerably more has changed in the last ten years than in the decades before, when every new model was in fact a further development of its predecessor. Every manufacturer goes through this development separately, but at the same time also with its competitors. Add to that again that the number of competitors by new entrants such as Tesla and the Chinese brands explosively increases and you understand the pressure under which manufacturers work.

Every car manufacturer has simply put two camps in -house: the development department and the marketing department. When the tight suits see that the competition brings something on the market on which their own white coats still work feverishly, the tight suits want to be able to offer it quickly, in order not to find out at the rivals. If at such a moment the engineers are not yet satisfied with the product they are working on, the marketers put them under pressure and complain to the board of directors. Under the adage ‘Who pays, it determines’ the marketing department often gets its way in practice. For example, it may happen that components of a new car often show weaknesses.

In addition, about the same goes for the costs. Increasing competition requires manufacturers to calculate as sharply as possible. Especially the Chinese entrants, who have considerably lower production costs, put great pressure on Western manufacturers. One of the ways to reduce your own costs as a car manufacturer is skimp on materials and suppliers, which in turn are under great pressure from their customers. As a result, defects are lurking due to inadequate components.

Long delivery times

Another problem that can occur because of that ‘skimp’ is a radical and long -term repair. Where manufacturers in the old days he took on large parts of the supply, the supply lines are now ‘Lean and Mean’. This means that components are only delivered shortly before the moment they are actually needed. This is called ‘Just in Time’ in logistical professional terms and it is a substantial saving post for manufacturers, because stocks cost money, interest, space and handling. The moment a certain component is unexpectedly needed in larger than usual quantities, you run into waiting times as a consumer.

Hyundai and Kia: Long waiting lists on loading regulator

That happens especially when the supplier gets into trouble. That happened last year the Hyundai Motor Group, which also includes Kia. Models built on the E-GMP (Electric Global Modular platform) could show defects in the ICCU, the Integrated Charging Control Unit, the control cabinet that makes it possible to charge and discharge, among other things. There is a weak transistor in that cupboard that, if it breaks, causes a fuse to burn out. From that moment on, the 12V battery is no longer charged, as a result of which part of the systems fails, which in turn leads to power loss in the high voltage circuit. The Hyundais IONIQ 5 and IONIQ 6 and Kia’s EV5 and EV6 are on this platform. Quickly to the dealer and therefore replace. At least, you would assume that, but a previous factory fire was created by the supplier for this component for this component.

No more loading with Ford Kuga PHEV

There is also good news. Because cars are defined more and more software, more and more errors with an update can be remedied, whether or not over The Air. A good example of this is the problem with the high -voltage batteries from Ford. The plug-in hybrid Kuga from before the facelift, so built between 2019 and 2024, can have problems with the battery, with some weak cells causing a short circuit. In such a case, the on -board computer summons the rider to ‘stop now’. In an extremely case, a fire can even occur in the battery.

To be ahead of such incidents, Ford advised earlier this year in a letter to all owners to no longer charge the Kuga PHEV until there was a solution and only to drive on gasoline and in the car EV mode, so that the gasoline engine also no longer charges the battery. There were quite a few people to write about it, because the Ford Kuga is a popular plug hybrid. No fewer than sixteen thousand copies of the affected building series are driving around in the Netherlands according to the figures from RDC and another three thousand copies in Belgium.

This led to quite a bit of indignation. Rijders stated that they had just bought the car to drive as much as possible and that, until there was a solution, they were confronted with higher fuel costs. Ford then provided a one -off allowance of € 200 and an extension of the warranty on the battery from five to ten years.

There is now a solution in the form of a software update. You would say that a software solution for a hardware problem is at most a patch, but according to Ford it is not at the expense of the battery performance. After all, it is not that the suspicious cells are switched off. They just continue to cooperate. However, the new software keeps a close eye on them and if something ever happens with it, then Ford will replace the battery. A smart and much cheaper solution than replacing the battery of all those kugas. Don’t forget: this type of recall action is usually a very small chance that something will go wrong with a certain series of cars.

Frustration about the on -board loaders of Stellantis

Significantly less easy to solve are the problems with the on -board loaders of Stellantis. Since 2019 it has been raining complaints from motorists with an electric car from this stable (see framework for all models). Charging on alternating current, so via the on -board charger, suddenly no longer works. In the Netherlands alone, 33,000 cars are sensitive to this problem, which appears to have its origins in the 11-KW on-board loaders (OBC) of the German supplier Mahle. In Belgium, 11,000 models drive around with a Mahle on-board loader. This manufacturer brought his lack of charger to the drawing board twice, but the adjustments could not eliminate the problem, to the great frustration of customers who had paid € 1,000 or even € 2,000 for a switch.

Stellantis replaced Mahle by a new supplier in 2024, but that is not a solution for customers who are still stuck in their car with a mahle. The affair was dealt with in the AVROTROS Radar consumer program (just like later the battery problem with the Ford Kuga PHEV), with which Stellantis was not sufficiently serious about the complaints of drivers. In the meantime, the car concerner has extended the warranty period of the on -board charger, partly at the insistence of the ANWB, from two to four years. Anyone who had their board charger replaced at your own expense can report this to the customer service, after which it will be considered whether and how much compensation will be paid.

It is remarkable that research by Radar shows that the service of Toyota, which has the same Mahle on-board loader in part of the proaces and therefore experiences the same problems, turns out to work much better oiled. What plays a role in this is that Toyota has been giving a 200,000 kilometer warranty for five years, which is even extended for up to ten years if the car continues to be given the prescribed periodic maintenance.

High quality

Incidentally, there was never a recall with this on -board lady, because something like that is only mandatory when safety is compromised by the problem. Radar criticizes the fact that owners of a car with Mahle-on-board loader were never proactively informed, while Stellantis had been aware of the possible problem for years, as witnessed by the fact that it had informed its dealers. Mahle himself, finally, only wanted to respond in writing to the questions of the radar editors, but that got no further than a standard tune over high quality and reliability and a hundred years of distinction from the competition.

What does the on -board charger do?

Take and give batteries direct current (DC, direct current) while electric motors need alternating current (AC, alternating current). When loading on the normal charging station, the alternating current in the on -board charger is converted into direct current for the battery, which when driving in the inverter becomes alternating current for the engine. Fast charging is done with direct current, so in principle outside the on -board charger. That is why with a defective on -board loader you can usually still fast load, but no longer on the regular charger.

These models of Hyundai Motor Group are on the E-GMP platform with a weak ICCU

Hyundai IONIQ 5, IONIQ 6, IONIQ 9 and KIA EV3, EV4, EV6 and EV9.

These models from Stellantis received a Mahle on-board loader during production

From July 2019 to July 2022:

2020 to 2023:

These models from Toyota can have a Mahle on-board loader:

Toyota Proace Electric and Proace Verso Electric

Toyota Proace City Electric and Proace City Verso Electric

New Cars Seem to Be Plagued with Electronic Defects More and More Often Straight From the Factory. This is also evident from research by JD Power. Fully Electric Models and Plug-in Hybrids, in particular, or Let Their Drivers Down. Autoweek Investigated Where this Trend Comes from and How Manufacturers Are Solving the Defects.

What is not on it cannot break, and with that old wisdom in mind, it is QUITE LOGical that malfunctions in New Cars Are Increasingly Attributable to Failing Electronics. Figures from the American Research Agency JD Power Underline This. A striking detail is that the number of problems per hundred cars, called jd power pp100 in the statistics, is 181 for Average Brands (2024 Figures, American Market), but no less than 230 for premium brands. This is due to the more complicated on-board Systems and the resulting Dependence on Connectivity, The Researchers Explain Thesis Disturbing Figures.

Electric Cars Less Maintenance and Less Prone to Malfunctions? The Opposite is True!

JD Powers Further Refutes The Often-Heard Claim that electric cars Require Less Maintenance and Are Less Prone to Malfunctions than Models with an Internal Combustion Engine, Becoaus they Contain Fewer Parts and Components. The Opposite Appears to Be the Case. Accordance to JD Power’s Automotive Chief Frank Hanley, Drivers of Fully Electric Cars and Plug-in Hybrids Report To The Workshop An Average of Three Times More Often with Malfunctions than Motorists Who Drive A Vehicle With Conventional Propulsion.

Neverbertheless, The Biggest Problem are Problems that you also Encounter in Modern Fuel Cars: False or Incomprehensible Warning Signals from the Adas, Malfunctions in the Connection with the smartphone and the new Operation of Cutback Physical buttons. Heavily is criticized by JD Power in the Latter Area, Tesla in Partularar.

Time Pressure Causes Errors

Admittedly, JD Power Limits its Research Area to the United States, But We On Our Of The Atlantic Ocean Cannot Ignore This Phenomenon Eigher, As Evided by A Number of Cases That Have OcceD in Recent Years. You can really wonder how it is Possible That Car Manufacturers, Where Hundeds of Highly Educated Engineers Work Hard On Things That Are Things Extensively Tested in The Most Extreme Conditions, So Often Drop Stitches.

Often It is time pressure that causes construction errors. This is how it works: The Development of Cars Has Accelerated in recent years. This is Largely Due to the Rise of the Various Forms of Electrification, but in Addition, The Range of Adas On Board is also Increasing Nogtown. MoreOover, Cars Are Increasingly Connected and We Expect (And Get) More and More Luxury on Board.

Newcomers Increase Pressure

All in all, you can saafely say that have bone praiseful more technical changes in the past ten years than in the decades before, when each new model was in fact a further development of its predecessor. Each Manufacturer Goes Through This Development Separately, But also simultaneously with its competitors. Add to that the fact that the number of competitors is Increasing explosive due to new entrants Such as tesla and the Chinese brands, and you understand the pressure under which manufacturers work.

Every Car Manufacturer Simply Has Two Camps In-House: The Development Department and the Marketing Department. When the suits see that the competition is Bringing Something to the Market that their Own White Coats Are Still Feverishly Working On, The Suits also because to be able to sacrifice it quickly Themselves, in order not to lag behind the rivals. If the Engineers are not yet satisfied with the product they are working on such a moment, The Marketers Put Them Under Pressure and Complain to the Board of Directors. Under the adage ‘He who Pays, Determines’, The Marketing Department of Gets Its Way in practice. This is how it can happen that components of a new car frequently show weaknesses.

In Addition, About the Same Applies to the Costs. Increasing Competition Forces Manufacturers to Calculate As Sharply As Possible. The Chinese Entrants in particular, Who Have Consider Fable Lower Production Costs, Put Great Pressure on Western Manufacturers. One of the Ways for a Car Manufacturer to Reduce Its Own Costs is to Cut Back On Materials and Suppliers, Who in Turn Are Under Great Pressure From Their Customers. As a result, defects due to defective components are lurking.

Long Delivery Times

Another problem that can arise from that ‘cutting back’ is a major and lengthy repair. Where Manufacturers Used to Maintain Large Stocks of Parts in The Past, The Supply Lines Are Now ‘Lean and Mean’. This means that components are only delivered shortly before they are actual needed. ‘Just in Time’ is what it is called in Logistics Terms and it is a Considerable Saving Item for Manufacturers, Because Stocks Cost Money, Interest, Space and Handling. The moment a certain part is needed unexpectedly in larger than usual quantities, you as a consumer will face waiting times.

Hyundai and Kia: Long Waiting Lists for Charging Controller

That happens all the more when the supplier gets into trouble. That happened last year to the hyundai motor Group, which also includes kia. Models builds on the e-GMP (Electric Global Modular Platform) Could Show Defects in the ICCU, the Integrated Charging Control Unit, The Control Box that Makes Charging and Disarian Possible, Among Other Things. In that box, a weak transistor is that, if it breaks, blows a fuse. From that moment on, the 12v battery is no longer charged, causing part of the systems to fail, which in turn leads to power loss in the high-voltage circuit. Among Others, The Hyundais Ioniq 5 and Ioniq 6 and Kia’s EV5 and EV6 are on this platform. Quickly to the dealer and replace it. At Least, You would assume, but a Previous Factory Fire at the Supplier Created Long Waiting Lists for This Component.

No More Charging with Ford Kuga PHEV

There is also good news. Because cars are increasingly software defined, more and more errors can be resolved with an update, Whether or not over the air. A Good Example Of This Is The Problem With Ford’s High-Voltage Batteries. The plug-in hybrid kuga from before the facelift, so build between 2019 and 2024, can have problems with the battery, with some weak cells causing a short circuit. In Such a case, the on-board computer Summons the Driver to ‘Stop Safely Now’. In an extreme case, there may be a fire in the battery.

To prevent Such Incidents, Ford advised all owners in a letter Earlier this year not to charge the kuga phev until a solution was found and to only drive on gasoline and in car EV Mode, so that the Gasoline Engine No Longer Charges the Battery. There were QUITE A FEW PEOPLE TO WRITE TO, because the Ford Kuga is a popular plug-in hybrid. Accordance to the figures from RDC, no less than Sixteen Thousand Copies of the affected series Are Driving Around in the Netherlands and Another Three Thousand Copies in Belgium.

This led to QUITE A BIT OF OUTRAGE. Drivers stateed that they had bought the car precisely to drive as much as possible electrically and that, until a solution was found, they were faced with higher fuel costs. Ford then provid a one-off compensation of € 200 and an extension of the battery warranty from five to ten years.

Meanwhile, there is a solution in the form of a software update. You would say that a software solution for a hardware problem is at most a stopgap, but accordance to ford it does not affect the performance of the battery. After all, it is not that the suspect cells are switched off. They just keep working. However, the new software keeps a close eye on them and if something ever happens, Ford will replace the battery anyway. A Smart and Much Cheaper Solution than Replacing the Battery of All Those Kugas. Don’t forget: with this type of recall, there is usuary only a very small chance that something that something will go with a certain series of cars.

Frustration about Stellantis’ on-board Chargers

The Problems with Stellantis’ on-board Chargers Are Considerly Less Easy To Solve. Since 2019, complaints have leg pouring in from motorists with an electric car from this stable (see box for all models). Charging On Alternating Current, ie via the on-board Charger, Suddenly No Longer Works. In The Netherlands Alone, 33,000 cars are susceptible to this problem, which appears to originate in the 11-kw on-board Chargers (OBC) from the German supplier Mahle. In Belgium, 11000 Models are Driving around with a Mahle on-board Charger. This manufacturer took his defective Charger Back to the Drawing Board Twice, But the Adjustments Could not Eliminate the Problem, much to the Frustration of Customers Who had Paid € 1,000 or € 2,000 for a switch.

Stellantis replaced mahle with a new supplier in 2024, but that is not a solution for customer who are still stuck with a mahle in their car. The Affair was Dalt With In The Consumer Program Radar from Avrotros (Just Like The Battery Problem With The Ford Kuga PHEV Later), which Stellantis did not take Complaints from Drivers Seriousous Enough. Meanwhile, The Car Company Has Extended the Warranty Period of the on-board Charger from Two to Four Years, Partly At The Insistence of the ANWB. Anyone Who had Their on-board Charger replaced Earlier At Their Own Expense Can Report This to Customer Service, After which it will be assessed on a case-by-Case Basic Whether and How much compensation Will Be Paid.

Remarkable, research by Radar shows that the service of Toyota, which has the same mahle on-board charger in part of the proaces and therefore experiences the same problems, appears to work much smoothly. What also plays a Role is that toyota already cool a five-year or 200000 kilometers Warranty anyway, which is just extended to ten the car continues to receive the prescribed periodic maintenance.

High Quality

Incidentally, there has never leg a recall in this on-board charger issue, because they only mandatory when safety is compromised by the problem. Radar criticizes the fact that owners of a car with a mahle on-board Charger Were Never proactively informed, while Stellantis had leg aware of the possible problem for years, as evidenced by the fact that it had informed its dealers. Finally, Mahle Himself Only Wanted to Respond in Writing to the Questions from the Radar Editors, But that Did Not Go Beyond a Standard Line About High Quality and Reliability and a Hundred Years of Distingughing Itelf From the Competition.

What does the on-board charger do?

Batteries take and give Direct Current (DC), While Electric Motors Need Alternating Current (AC). When Charging at the Normal Charging Station, The Alternating Current In The On-board Charger is Converted Into Direct Current for the Battery, which in the Inverter Becomes Alternating Current For The Motor When Driving. Fast Charging is Done with Direct Current, so in principle outside the on-board Charger. Therefore, with a defective on-board Charger you can usualy Still Fast Charge, But No Longer at the Regular Charger.

These Models from Hyundai Motor Group Are on the E-GMP Platform with a WAK ICCU

Hyundai IONIQ 5, IONIQ 6, IONIQ 9 and KIA EV3, EV4, EV6 and EV9.

These Models from Stellantis Were Fitted with a Mahle On-board Charger Duration Production

From July 2019 to July 2022:

2020 Up to and Including 2023:

These Toyota Models May Have A Mahle On-board Charger:

Toyota Proace Electric and Proace Verso Electric

Toyota Proace City Electric and Proace City Verso Electric