The “Intel Inside” of Cars

Startup DeepDrive claims to have reinvented the electric motor with an innovative hub motor. Is this the drive of the future?

Alex Rosen, one of DeepDrive’s founders, has a clear goal: “We want to become a brand so strong that car manufacturers refer to our motor and state ‘DeepDrive inside’ on it, similar to the ‘Intel inside’ slogan for computers.” A particularly ambitious goal, one might say. To date, only a few suppliers have shown interest, such as Brembo, a leading manufacturer of braking systems. But to be fair, so far DeepDrive has achieved all its intended milestones.

Mounted in a Tesla Model 3

Recently, the first wheel hub motors from the Munich-based startup were mounted in a Tesla Model 3. The test car has already covered more than 2,500 kilometers without problems. In the autumn, the DeepDrive-modified Tesla was presented to the world at the Salzburgring in Austria. Impressive drifts were also performed, which are possible because the drive unit is mounted directly on the wheel. This enables torque vectoring: the power of the drivetrain can be allocated to specific wheels, or even all four wheels, depending on driving conditions.

Into the Snow in March 2026

Testing continues; from March 2026, the car must prove itself in Scandinavia in winter conditions tests. DeepDrive’s motors are expected to be used in a production model for the first time in 2028. The company does not yet want to say which brand has placed the order; it is certainly not Tesla. DeepDrive chose a Tesla as a test car for neutrality: “We can’t approach Volkswagen with a Renault, or vice versa,” says Rosen.

Saving 30 kilograms

In DeepDrive’s premises in Munich-Garching, the test Tesla is on the lift, with the original Tesla electric motor that previously provided the drive placed in front of it. Where that motor used to be, there is now a hole the size of a beer crate. The motors are now mounted on the left and right rear wheels. “This way we save a total of thirty kilograms in the Tesla,” says Rosen. And then there’s the advantage of space saved. This makes it possible to mount a larger battery or a larger trunk, or simply a more compact construction.

A Hub Motor Makes an Electric Car More Efficient

And then, of course, there is the improved efficiency that the company claims: according to DeepDrive, the hub motors consume 20 percent less energy than conventional electric motors. Whether this can truly be achieved will soon be demonstrated by tests. First, a new set of tires must be mounted on the test car, because the current ones are significantly worn. “The car has been put to the test extensively,” says Alex Rosen. During various demonstration drives, customers from the automotive industry thoroughly tested the DeepDrive-Tesla, including on poorly surfaced and unpaved roads. “It hurts to see how people drive the car with the goal of testing it to the limit,” says Rosen. However, this did not cause any problems: the motors passed the intensive tests well.

Wheel Hub Motor Revived

Incidentally, wheel hub motors are practically as old as the car itself (see box), but due to the rise of the internal combustion engine, the technology – like the electric car in general – fell into oblivion. Now DeepDrive wants to breathe new life into this technology. The ‘double rotor’ problem has already been tackled. “It has been discussed for decades, but until now it had not been solved,” Rosen explains. The concept of these drive units has existed for a long time, but until now no manufacturer had managed to implement it properly.

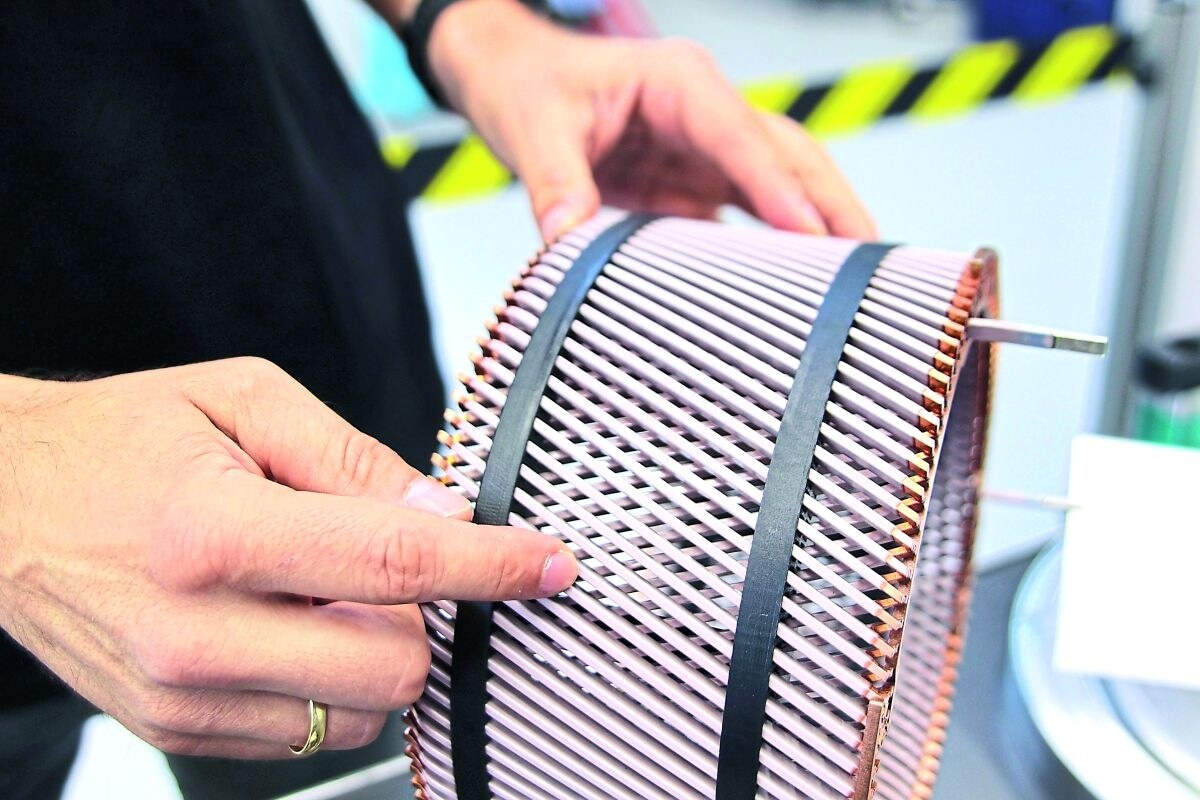

Grille Structure

The chief developer shows us the most important component: the double rotor features a grille structure made of a copper alloy. This frames the stator on both sides, thus doubling the electromagnetic impulses that set the rotor – and with it the wheel – in motion. The grille structure must be extremely stable to withstand high speeds and severe shocks for extended periods. How did DeepDrive achieve this? That’s a trade secret. In any case, the construction has passed all load tests.

Support from BMW, Volkswagen and Continental

While DeepDrive receives support from BMW, Volkswagen, and Continental, it is not bound to a specific manufacturer or supplier. “We can sell our motors to any manufacturer,” says co-founder Rosen. The company is currently in talks with eight of the ten largest automotive groups worldwide, including German, European, Japanese, and Chinese manufacturers. The industry is certainly interested in the small company’s hub motor. BMW even considers the DeepDrive drive unit to be the ‘next-generation electric motor,’ and Volkswagen also has an interest: through the venture capital provider Leitmotif from California, Volkswagen is supporting the Munich-based startup as part of a second financing round totaling thirty million euros. However, DeepDrive does not intend to carry out the series production of the motors themselves. For this, the company has entered into a partnership with Continental. This German supplier will build the in-wheel drive unit on commission.

Technical Expert Cornelis Kit Has Doubts About the Hub Motor

“The first acquaintance with the DeepDrive hub motor is positive, yet there are still a few loose ends. Although regenerative braking is possible, brake discs or drums remain necessary. This increases the unsprung mass, which negatively affects handling (and thus safety). Furthermore, we are curious about the lifespan. The motor in the wheel is close to dirt and moisture. In addition, the motor unfiltered receives all irregularities in the road surface as impacts. Finally, we are curious about the thermal management. How is the motor cooled, and what is the effect of, for example, hot brakes? Torque vectoring does not necessarily require hub motors; it can also be done very well with in-board motors more efficient, all manufacturers would already have this technology in their showrooms.”

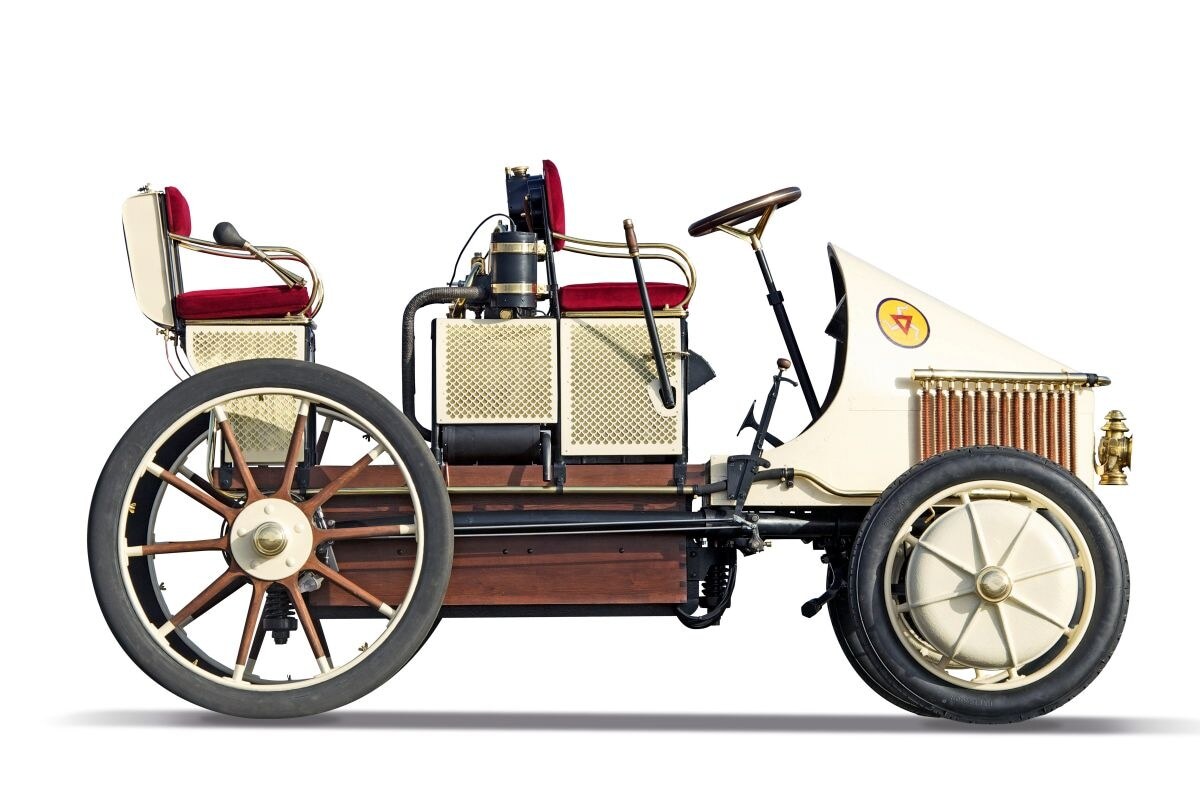

The Wheel Hub Motor: As Old As the Car Itself

As early as the late nineteenth century, there were cars with electric motors placed in the wheel hub. Even then, the pursuit of better efficiency was an important driver, as the first internal combustion engines were connected to the wheel via a belt, which consumed a lot of energy. Ferdinand Porsche’s Lohner-Porsche changed that. The engineer, who later led the development process of the Beetle, had built hundreds of cars with hub motors between 1887 and 1906 at the Lohner factory in Vienna. Ludwig Lohner, the imperial court automobile supplier of the then Danube Monarchy, saw potential in Porsche’s plans because he found it a bad thing that the outdoor air was “mercilessly polluted by the large number of gasoline engines,” according to a contemporary source. However, it soon became clear what the Achilles’ heel of the Lohner-Porsche and all other electric cars of that era was: their lead-acid batteries were too weak. They provided a range of barely fifty kilometers, and it took several days to fully recharge the batteries.

From Student Room to Start-up

DeepDrive’s founders with more than ten years ago. They were fellow students. They also worked together on cars: the young engineers were members of ‘TUfast’, the student-led motorsport team of the Technical University of Munich. Here they engaged in technical developments in various branches of sport, including the ‘MotoElectric Team’. During that period, the idea for the startup emerged. After their studies, DeepDrive’s founders started working at Bosch and further developed their plan there, which resulted in the establishment of a startup in 2021.